Share

Annealing is a process by which steel is reheated and then cooled to make it less brittle. Consider the reheat stage for a 100-mm-thick stee

Question

Annealing is a process by which steel is reheated and then cooled to make it less brittle. Consider the reheat stage for a 100-mm-thick steel plate ( 7830 kg/m3, 550 J/kg·K, 48 W/m·K), which is initially at a uniform temperature of 170°C and is to be heated to a minimum temperature of 550°C. Heating is effected in a gas-fired furnace, where products of combustion at [infinity] 800°C maintain a convection coefficient of 250 W/m2·K on both surfaces of the plate. How long should the plate be left in the furnace?

in progress

0

Physics

4 years

2021-08-21T14:44:55+00:00

2021-08-21T14:44:55+00:00 1 Answers

611 views

1

Answers ( )

Answer:

The answer to the question is;

The plate be left in the furnace for 905.69 seconds.

Explanation:

To solve the question, we have to check the Bi number as follows

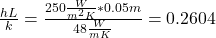

Bi =

As the Bi number is > 0.1 we have to account for the variation of temperature with location in the mass.

We perform nonlumped analysis

The relation for heat transfer given by

Y =

= = 0.3968 = C₁ exp (ζ₁² F₀)

= 0.3968 = C₁ exp (ζ₁² F₀)

where

C₁ and ζ₁ are coefficients of a series solution

We therefore look for the values of C₁ and ζ₁ from Bi tables to be

ζ₁ = 0.4801 +(0.26-0.25) (0.5218-0.4801)/(0.3-0.25) ≈ 0.4884 and

C₁ = 0.4801 +(0.26-0.25) (1.0450 – 1.0382)/(0.3-0.25) ≈ 1.03956 and

This gives the relation

0.3968 = 1.03956 exp (ζ₁² F₀)

or ζ₁²

where

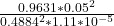

α = Thermal diffusivity of solid = k/(ρ·c ) =

) =  = 1.1146×10⁻⁵

= 1.1146×10⁻⁵

c = Specific heat capacity of solid at constant pressure = 550 J/kg·K

= Specific heat capacity of solid at constant pressure = 550 J/kg·K

ρ = Density of the solid = 7830 kg/m³

=㏑ = -0.9631 from where we have

= -0.9631 from where we have

t = = 905 seconds.

= 905 seconds.